Model NO. : D002003001D

Layout Type : Verticle

Mixing Drum Shape : Disc

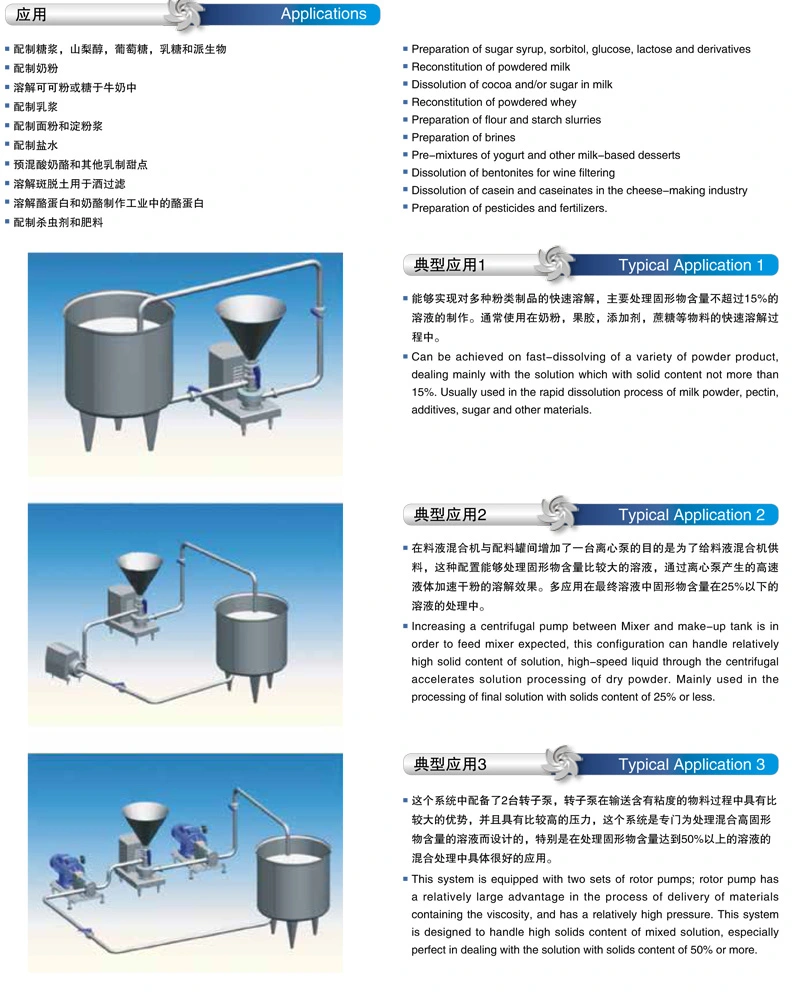

Additional Capabilities : Milling

Operating type : Cycle Operating

Condition : New

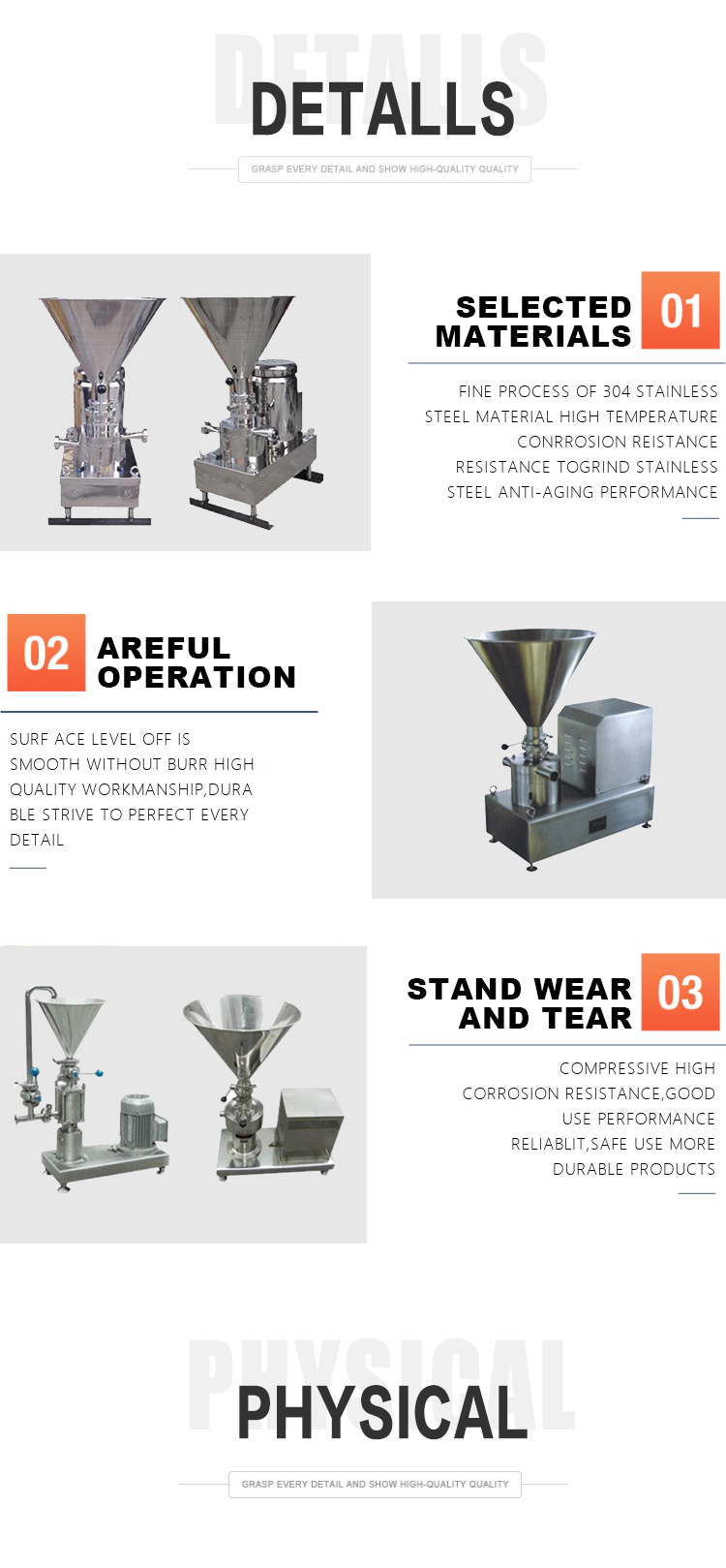

Material : Ss304,Ss316L

Motor : ABB Motor

Power : 120degree Celsius

Connection : Clamp,Threaded

Capacity : 10ton, 20ton, 30ton, 40ton, 50ton

Standard : SMS,DIN

Pressure : 0-10bar

Model : Hhb-10~Hhb-50

Hopper Volumn : 45L~65L

HS Code : 8413709990

Trademark : XUSHENG

Specification : ISO, 3A, SGS

Transport Package : Shrink Wrap-Carton Case-Exporting Plywood Case

Origin : Wenzhou City, China

Inquiry

Inquiry Contact Us

Contact Us